Working on the seats and driver restraint system mounting points. The first thing I did was locate the seat in the car for maximum driver comfort. Then holes were drilled through the seat and floor. There are no mounting provisions for aftermarket aluminum sheetmetal seats in these old Corvettes as you can see

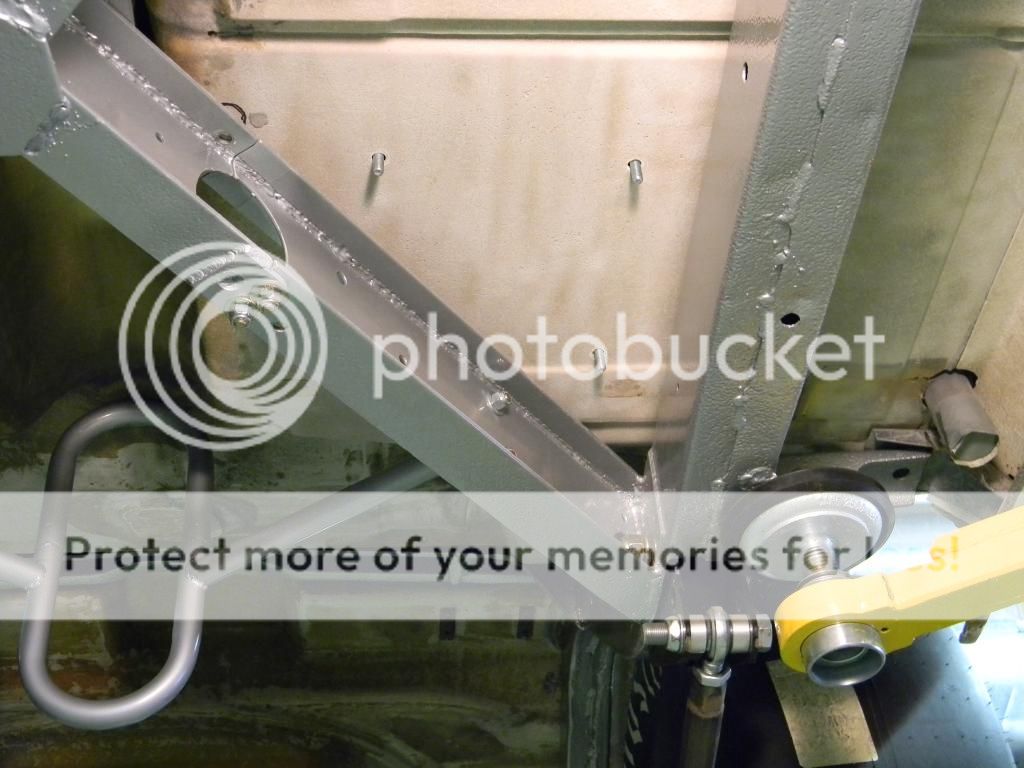

I welded a piece of 1" X .095 Chrome-Moly tubing in place as a cross member. This provides a structure that would be suitable for the seat mounts as well as the "crotch strap" mounting point.

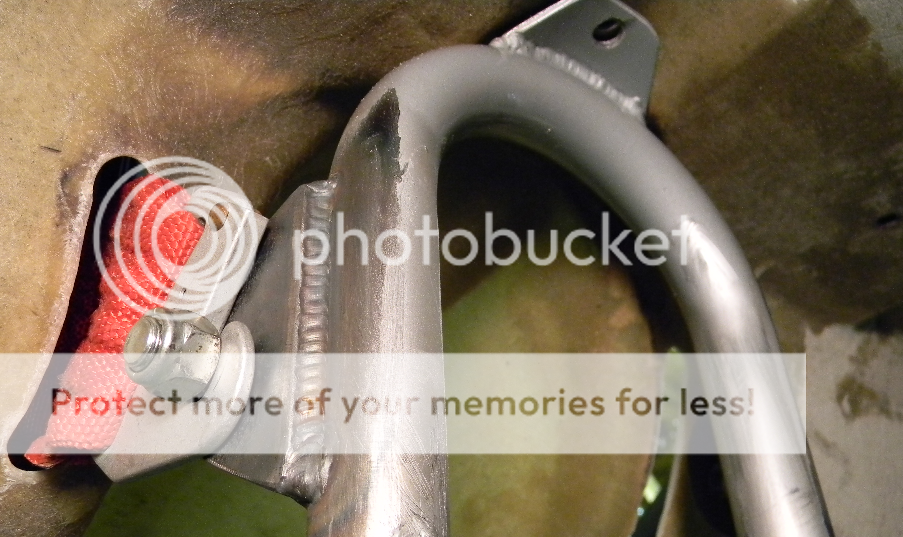

I had to come up with a mounting point for the inside lap belt (closest to the drive line tunnel). So I welded tabs to the drive line loop cross member. The cross member loop also attaches to the body at the top of the loop for additional support. Note: This belt is an old belt and not correct for this type of anchor design, and only used here for visual mounting alignment.

I made the seats from .080 aluminum sheet in two pieces. The bottom is completely welded to the wrap around back and sides. 1/2" round aluminum stock is then formed and solid welded all the way around except across the front bottom. The seats were then powder coated in black wrinkle finish. Four panels make up the seat interior (the bottom, back, and two "L" shaped sides)

Wade Mahaffey