|

|

|

|

#1 |

|

VIP Member

Join Date: Oct 2013

Location: Gulf Breeze, FL

Posts: 1,651

Likes: 8

Liked 33 Times in 16 Posts

|

A friend and I picked this car up a while back and we are working on it this winter with many upgrades in store. Car came to us with a Powerglide and numerous small problems...we are whittling them down one at a time.

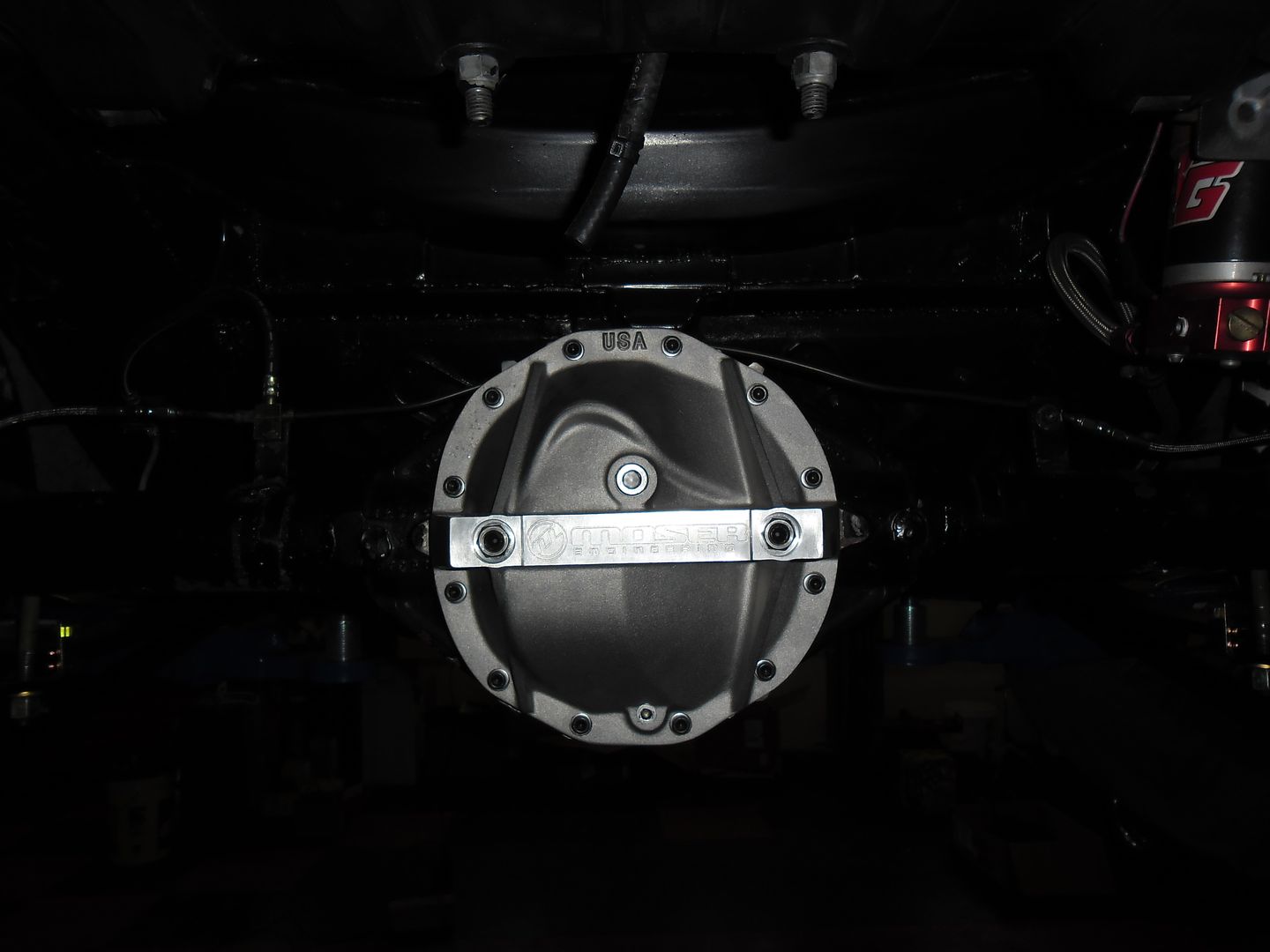

As of this evening these are the completed items: Complete re-wire of the ignition system - New MSD distributor and coil - Altered bracketry for the Moroso water pump - New 5.14 Richmond gear - Caltrac's for the rear with Caltrac split leaf springs - New Moroso front springs - New shocks on all corners - Aerospace disc brakes front and rear and light weight master cylinder - Improved gauge package - New Champion wheels all around - (I splurged a bit here  ) )Just about all problem areas have been addressed save one...Arnett is building us a Metric 200 atm and a ATI convertor will be added as well when it's ready. Come spring we will find out how good a motor we have in the car...can't think of anything else that would hold us back. The car is already very close to the class minimum weight for a 286/350 in E/SA.

__________________

Rich Taylor I/SA - 321 Last edited by HandOverFist; 11-30-2013 at 05:16 PM. Reason: added better photo's |

|

|

|

|

|