|

|

|

#1 |

|

VIP Member

Join Date: Jan 2009

Location: Bardstown, KY

Posts: 1,930

Likes: 100

Liked 329 Times in 117 Posts

|

I love the looks of the 2008-2014 Cobra Jets but there was no way I could afford one.

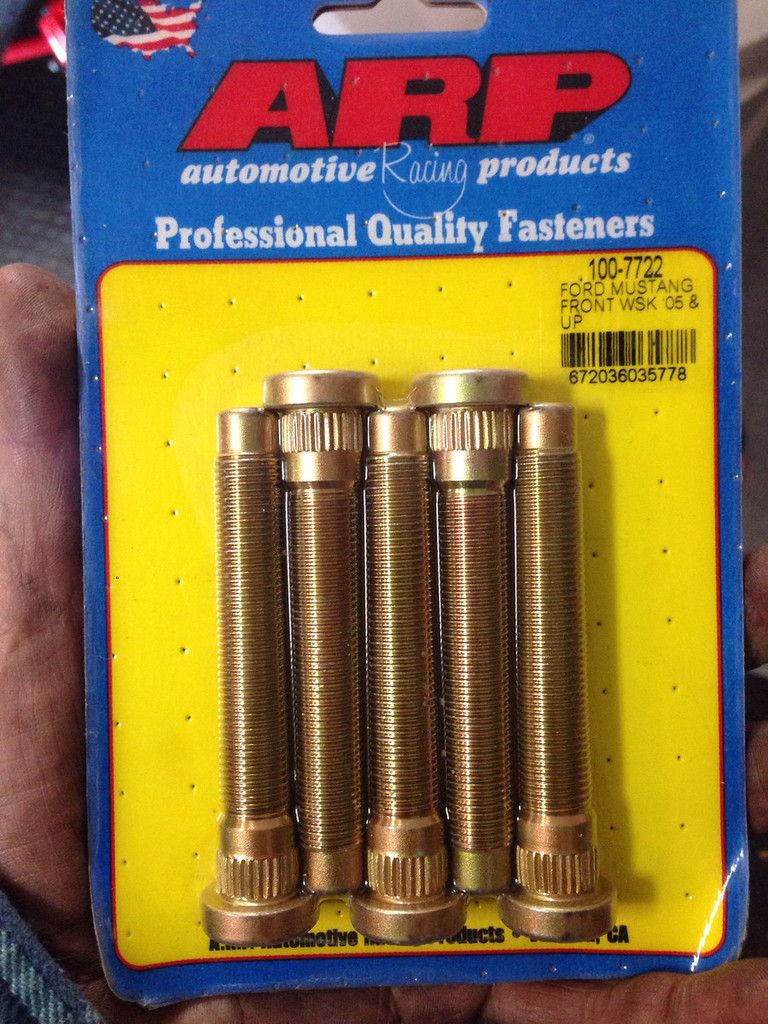

This is as close as I will get, so here goes the story of the build of my S197 Mustang 3 Valve GT up to the point that I took it to the Div. 3 race at Indy in late April. I wanted to build it for H/SA and see what the car would run with the required Stock Eliminator mods done to the car. Link to that day @ Indy: http://classracer.com/classforum/showthread.php?t=62048 After thinking about building one of these cars and searching all the ads on the internet for over a year, I finally got my big break in late Feb. of this year. A friend sent me a screenshot of a rebuilt 2005 Mustang GT and I found the CL ad. Up to this point it was the cheapest 3 valve GT I could find. I contacted the owner and locked in a deal where I would be the first person to look at the car. After looking at it and driving it for 5 minutes, I threw the seller an offer and we exchanged cash for the title. The car had been hit front and rear and was rebuilt with a clean KY rebuilt title. I had my car, but now I had to work fast to get it ready for Indy. The car mechanically checked out good. It had fantastic anti-lock brakes, strong engine and the trans felt fine. This was the very first 3 valve Mustang GT I had ever driven. Up to that point I had been used to my 95 Mustang GTs. The A/C and power steering felt great. Too bad because both would soon be taken off.    It had the wrong headlights, turn signal markers, and was missing the lower grille and left rear side marker. I managed to get a set of headlights locally for 40 bucks. The other items I had to get on ebay because the local salvage yard here did not have any 2005 and newer Mustangs. So I paid about $ 140 for all the correct lights, markers and grill, so now the body of the car was legal.  The first mod would be to allow my skinny drag wheels to work. These cars have huge (and heavy) front brakes but require a special part number ARP studs. Thanks to the S197 forums, I armed myself with enough info to order the correct 3 inch wheel studs and a stud installer. All 10 studs were $ 123.00 delivered. Not cheap, but they are the only ones I could find.  I also purchased a stud installer for 23 bucks. That is one great tool. I would screw a lug nut on the old stud, lightly tap on the stud while applying pulling pressure on the backside of the hub with a crowbar to try and absorb some of the impact of the hammer. Those hubs are sealed and non serviceable, so I did not want to damage the bearings any more than possible. ( I put a lug nut on the old stud while hammering it out to prevent it from hitting the ABS tone ring )   All 5 studs were installed in less than 20 minutes and the wheel fit perfect.

__________________

Alan Mackin Stock 3777/ SS 3377 P/SA & SS/PA Fox Thunderbird I/PS '95 Mustang GT Last edited by ALMACK; 05-03-2016 at 01:09 PM. |

|

|

|

| Liked |

|

|

#2 |

|

VIP Member

Join Date: Jan 2009

Location: Bardstown, KY

Posts: 1,930

Likes: 100

Liked 329 Times in 117 Posts

|

Next up for ol' Prep H was the driveshaft loop : $ 20.00 swap meet special with grade 5 bolts. 1/4 " x 2.0 as per spec.

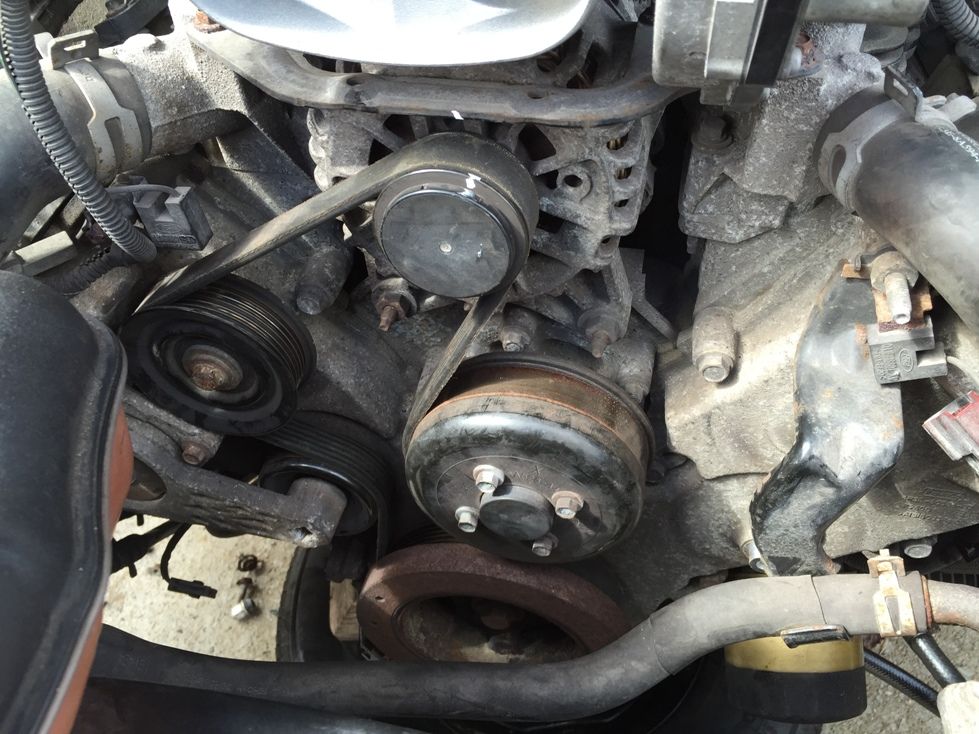

After that came the removal of the power steering pump and A/C compressor. I re-arranged the front pulleys and took the grooved one on the driver's side and put it onto the passenger side. Then I found a 49.5 inch belt in my stash of parts and tried it. Dead on perfect ! What luck. Now I had my short belt.   Now I had my alt. and water pump as the only items drawing from the engine. Eventually I want to put an electric water pump on the car and relocate the alternator down low on the pass. side, but those pumps are over 400 bucks new. Maybe later.

__________________

Alan Mackin Stock 3777/ SS 3377 P/SA & SS/PA Fox Thunderbird I/PS '95 Mustang GT Last edited by ALMACK; 05-03-2016 at 12:56 PM. |

|

|

|

| Liked |

|

|

#3 |

|

VIP Member

Join Date: Jan 2009

Location: Bardstown, KY

Posts: 1,930

Likes: 100

Liked 329 Times in 117 Posts

|

This is the first fitting of the wheels and tires that I "borrowed" from my Bronco II drag truck.

The front 26 inch tires did not look good with the Mustang's wheel opening. So I used some Hoosier 28 inch tall front drag tires that I had bought from a friend for 100 bucks. With mounting and balancing I had $130.00 into my skinnies now. That 4wd look in the rear would be fixed later...

__________________

Alan Mackin Stock 3777/ SS 3377 P/SA & SS/PA Fox Thunderbird I/PS '95 Mustang GT |

|

|

|

| Liked |

|

|

#4 |

|

VIP Member

Join Date: Jan 2009

Location: Bardstown, KY

Posts: 1,930

Likes: 100

Liked 329 Times in 117 Posts

|

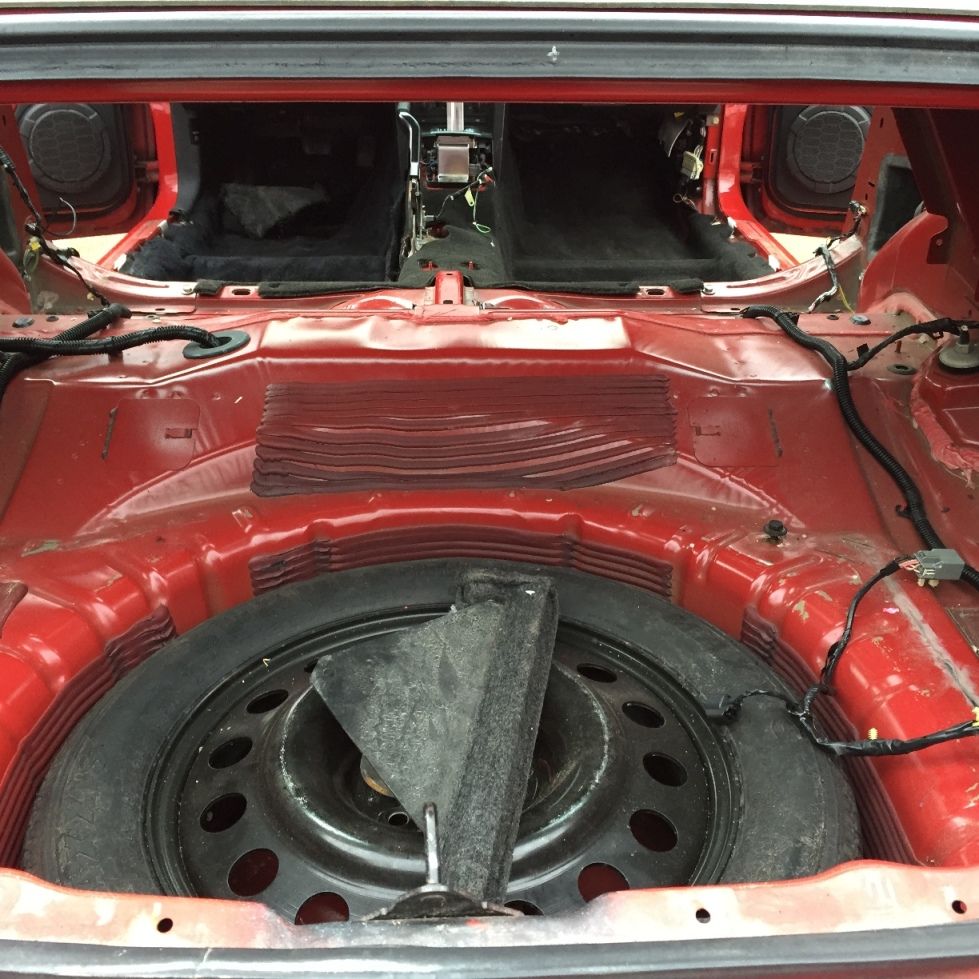

Now the fun begins...this was where I started to get nervous. I did not know how the interior panels were held into place and I did not have a service manual showing an exploded view of the panel layout.

So, I just slowly pulled on a panel until it popped. I gotta say, that sound still makes me quezzy, but luckily after the whole interior was taken out, I had only broke one tab, and that was because I took the trim out over the passenger door out of sequence. Notice how the door panel leather trim is sagging down...a common problem on these cars. Some time with 3M headliner adhesive and thoroughly cleaning off the old gray foam from the panels fixed that. Now that I know the sequence of removal and replacement, it would easier if the need arises. Not shown is the huge Shaker system speaker and amp box that was located on the pass. side in the trunk. It weighed exatly 60 lbs by itself !

__________________

Alan Mackin Stock 3777/ SS 3377 P/SA & SS/PA Fox Thunderbird I/PS '95 Mustang GT Last edited by ALMACK; 05-03-2016 at 01:04 PM. |

|

|

|

| Liked |

|

|

#5 |

|

VIP Member

Join Date: Jan 2009

Location: Bardstown, KY

Posts: 1,930

Likes: 100

Liked 329 Times in 117 Posts

|

After searching the net for a roll bar kit, I felt the 8 point S&W Race Parts kit was best suited for how I wanted the bar fit the car.

My primary goal was to retain the factory seats and not have to cut the door arm rests for the side bars. Mission accomplished on both. Dealing with S&W was a great experience. Very professional and knowledgeable.   I was concerned how I was going to be able to lower the main hoop down to weld the rear bars to the top of the hoop, but luckily Ford already provided me with the answer. These plugs pop out and with a slight stretch of the feet of the main hoop, they fit thru the holes.

__________________

Alan Mackin Stock 3777/ SS 3377 P/SA & SS/PA Fox Thunderbird I/PS '95 Mustang GT Last edited by ALMACK; 05-03-2016 at 01:02 PM. |

|

|

|

| Liked |

|

|

#6 |

|

VIP Member

Join Date: Jan 2009

Location: Bardstown, KY

Posts: 1,930

Likes: 100

Liked 329 Times in 117 Posts

|

This was my very first time installing a roll bar, and I have to admit it was very intimidating to me at first until I tackled the job.

It gets tedious. Lots of fitting, remove, grind, re-fit, grind some more....and so on, and so on. Now I know why chassis and fab shops charge what they do for a roll bar installation. A lot of time is involved to get it to fit within the tight confines of these late model cars. I could have just hacked up the back seat and drove the rear bar thru the cushion, or replace that lightweight seat with carpeting, but I love the look of the car's factory interior. Besides, the rear seats all combined can't be more than 20 lbs.  What I liked about the S&W kit was how the rear bars worked in the car...thru the package tray.  As a racer that works by myself quite a bit, I have to get inventive on how to hold items without a second set of hands. I fabbed up 2 brackets that bolted to the factory seat belt anchors and was fully adjustable. I could now move the main hoop forward or backwards or left to right to obtain a perfect and consistent position:  Now I had the ability to hold the hoop in the same position all the time. I had to revise it a couple of times, but this would turn out to be one of the best tools I built for this build.

__________________

Alan Mackin Stock 3777/ SS 3377 P/SA & SS/PA Fox Thunderbird I/PS '95 Mustang GT Last edited by ALMACK; 05-03-2016 at 01:32 PM. |

|

|

|

| Liked |

|

|

#7 |

|

VIP Member

Join Date: Jan 2009

Location: Bardstown, KY

Posts: 1,930

Likes: 100

Liked 329 Times in 117 Posts

|

At this point it is taking up a lot of my evenings after work. Plus I have to deal with mother nature as I do not have a garage.

My "garage" is well ventilated and well lit on sunny days...lol  Another set back was figuring out the head rest problem. These cars come from the factory with forward angled headrests, but when the rear seat back angle cannot be reclined due to the seat bar, the head rest is too far forward.  I tried figuring out how to pull them out, but no luck. Finally, as a last resort, I went on you tube and found the answer. A piece of wire stuck into the little hole is what released the headrest. I just turned them around for now. There is a company that makes adjustable versions, but they are not in my budget for now.  Next came fitting the side bars. I was relieved to see that the bars do not interfere with the arm rests and I can sit in the seat comfortably.

__________________

Alan Mackin Stock 3777/ SS 3377 P/SA & SS/PA Fox Thunderbird I/PS '95 Mustang GT Last edited by ALMACK; 05-03-2016 at 04:40 PM. |

|

|

|

| Liked |

|

|

#8 |

|

VIP Member

Join Date: Jan 2009

Location: Bardstown, KY

Posts: 1,930

Likes: 100

Liked 329 Times in 117 Posts

|

I had a set back with getting an appointment with my welder, so I lost a week. In the meantime I was buying as much used parts as I could to keep the costs down.

Luckily for me, the 2005-2009 GT parts are getting cheaper because alot of guys are stepping up to the 2011-2014 Coyote Mustang GT and selling off their 3 valve stuff. I got a hardly used JLT series 3 Cold Air Intake for $ 150.00 delivered around the same time I bought the wheel studs. Super nice condition. They sell for $ 240 new plus shipping. I had to get my CAI before I could order my tuner because they need to know what type of CAI you are using before they can program the tuner.  No discount on the X4 tuner. Everybody pretty much sells them for the same price. Besides, this was one item I had no interest in buying as a used item.

__________________

Alan Mackin Stock 3777/ SS 3377 P/SA & SS/PA Fox Thunderbird I/PS '95 Mustang GT Last edited by ALMACK; 05-03-2016 at 02:11 PM. |

|

|

|

| Liked |

|

|

#9 |

|

VIP Member

Join Date: Jan 2009

Location: Bardstown, KY

Posts: 1,930

Likes: 100

Liked 329 Times in 117 Posts

|

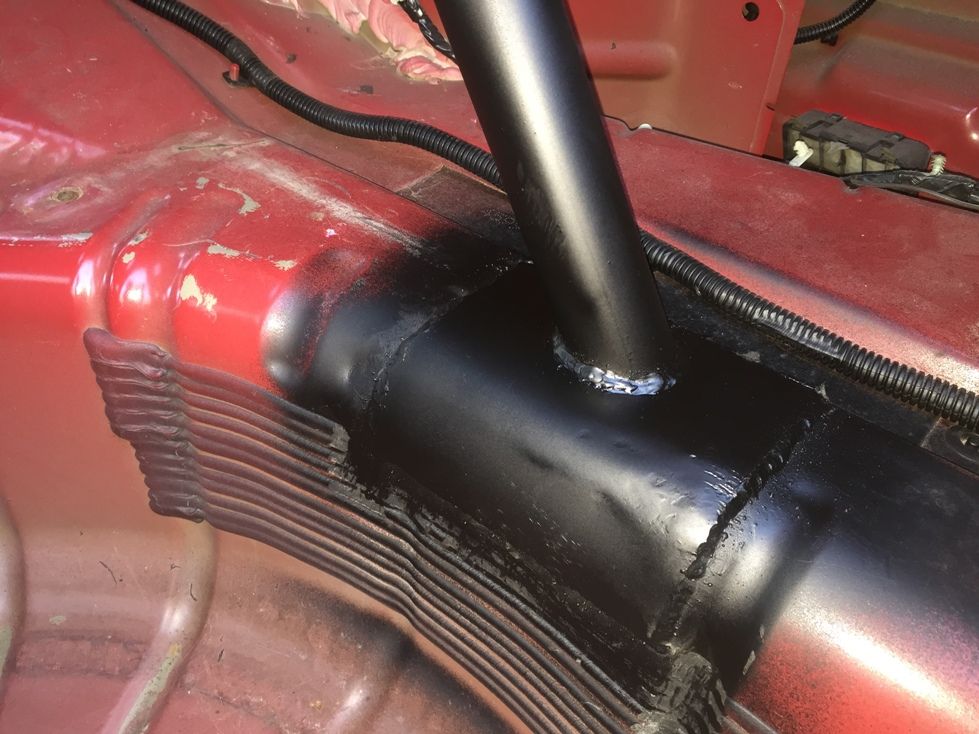

So my day at the welder came. Everything went perfect. All the planning and prep work paid off.

From the time the car went into his shop until I drove out was 2 1/2 hours. Everything fitted perfect and I was super happy there were not any burn marks on the interior panels. He had done alot of roll bar installations before, so he had all the right protective equipment. These pics were taken the day after the welding was done, and within 24 hours of getting back from his shop, the interior was all back in the car.   I had the passenger side seat belt tabs welded on while there so in the future they will be there when I drive this car on the street.  Trunk area rear bar mounts   I found this at Lowes and really like this paint. Goes on nice and is great on touch ups as it blends well with the existing paint. Plus, that satin look is my favorite look for a roll bar.

__________________

Alan Mackin Stock 3777/ SS 3377 P/SA & SS/PA Fox Thunderbird I/PS '95 Mustang GT |

|

|

|

| Liked |

|

|

#10 |

|

VIP Member

Join Date: Jan 2009

Location: Bardstown, KY

Posts: 1,930

Likes: 100

Liked 329 Times in 117 Posts

|

When it came time for the seat belt installation, I had to fab up a h.d. 1/2 inch bolt bracket for the belt on the trans tunnel side. (I used the factory seat belt bolt hole on the door side)

The factory seat belts anchor to the seat. The 3 inch racing belts need to be alot better than that. So I took a piece of 1/4 in. steel plate and bent it to the shape of the floor. Then I welded a 1/4 inch bolt to the plate to help hold the assembly to the floor. The grade-8 1/2 inch bolt is captured by the welded tab on the backside. This prevents the 1/2 bolt from turning when I tighten down the nut. No welding on the grade 8 bolt means no loss of strength.  Here is a shot from under the car after installation:

__________________

Alan Mackin Stock 3777/ SS 3377 P/SA & SS/PA Fox Thunderbird I/PS '95 Mustang GT |

|

|

|

| Liked |

|

«

Previous Thread

|

Next Thread

»

|

|

All times are GMT -4. The time now is 07:31 PM.

Linear Mode

Linear Mode