|

|

|

|

|

|

#1 |

|

Junior Member

Join Date: Mar 2008

Posts: 73

Likes: 0

Liked 0 Times in 0 Posts

|

Had a little time yesterday to work on the "Z". I straightened up a couple places on the firewall so I'd have a straight clean edge to start rebuilding. Then I made one of the two wells the intercooler tubes will pass through. I might use this one or I may try another approach. I'd like the mating surface to be a little smoother than this one. [shrinker sorta' wrinkled it a little]. This is my first attempt at any ''real'' metal shaping so there may be a few trial & error attempts on this deal.

|

|

|

|

|

|

#2 |

|

Junior Member

Join Date: Mar 2008

Posts: 73

Likes: 0

Liked 0 Times in 0 Posts

|

I changed up the design of the firewall some. The change affected the shape of the intercooler flange wells. I decided to stamp the parts, I guess mainly because I wanted to give stamping a try.

I cut dies out of 3/4" MDF board & stamped the sheet metal on the press.  then I rough trimmed the parts.  cleaned them up  Welded the front & back halves together  Once I had the tube flanges where I wanted them I welded them together.

|

|

|

|

|

|

#3 |

|

Junior Member

Join Date: Mar 2008

Posts: 73

Likes: 0

Liked 0 Times in 0 Posts

|

Sorry I got carried away on the project & by the time I remembered to take pictures I had the outlet tube firewall sheet metal done.

This is the firewall before...  and with the intercooler tubes part of the sheet metal in place.   The inlet side is just a simple pie plate deal that will be trimmed & welded into the firewall eventually. The outlet side was a little more complicated. I didn't want to run the plumbing off to the side (the way it's usually done). I wanted the carb hat facing straight back. Also, the engine is set back about 4" from the stock location. So, the 4" inlet tube has about 3/8" clearance between the windshield and about 1" clearance for the distributor. It's all pretty close but it fits. . The "through the firewall sheet metal'' for the inlet tube ended up looking sorta like shoving the flange through a hefty hefty trash bag.  ...and here's what it looks like from "the office".

|

|

|

|

|

|

#4 | |

|

VIP Member

Join Date: Sep 2009

Location: Barberton Ohio

Posts: 1,114

Likes: 0

Liked 0 Times in 0 Posts

|

If youre building a stocker Im seriously depressed, VERY VERY Nice work though......and Ill be resigning my overthing do it to the max overkill hat to you ........very very nice work.

But where did I miss what youre building ? Very very nice work especially the sheet work...... Quote:

__________________

Chris "Drooze" Wertman 3132 (F/SA 2009 Challenger Drag Pak #24 with a best of 10.59) |

|

|

|

|

|

|

#5 | |

|

Junior Member

Join Date: Mar 2008

Posts: 73

Likes: 0

Liked 0 Times in 0 Posts

|

Quote:

It's a 70 Z-28 RS

|

|

|

|

|

|

|

#6 |

|

Junior Member

Join Date: Mar 2008

Posts: 73

Likes: 0

Liked 0 Times in 0 Posts

|

Forgot I took some shots of the process when I stamped the shallower inlet side.

I cut the 3/4" MDF out on the CNC. I gave one side 1/8" clearance for the metal and the other side the circle press fit into the MDF.   This made the die the right depth (I needed it to be stamped 1/2" deep for the right offset). It also made it easy to register the die halves.  Once out of the press all I had to do was hammer the tucks and it's ready to trim to the firewall. The firewall that doesn't exist yet. |

|

|

|

|

|

#7 |

|

Junior Member

Join Date: Mar 2008

Posts: 73

Likes: 0

Liked 0 Times in 0 Posts

|

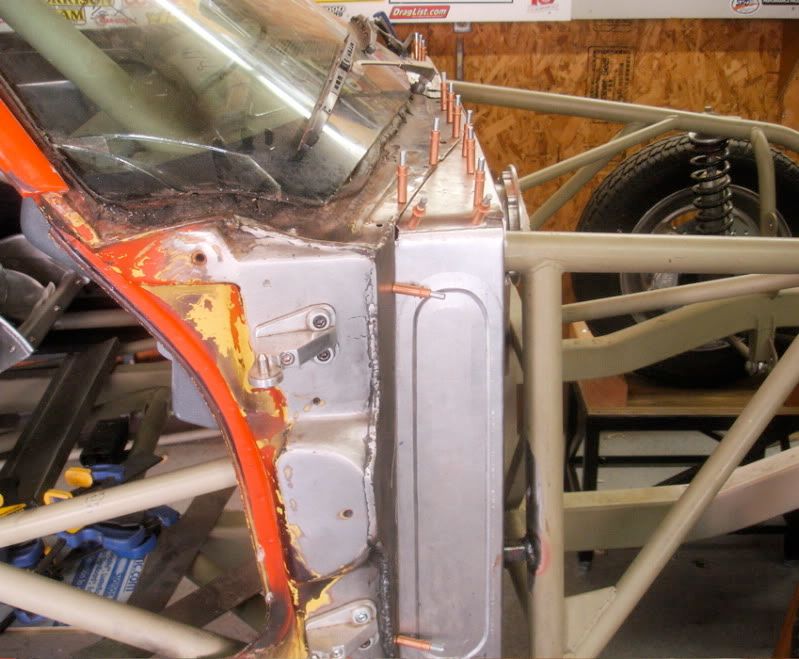

Got a little more done on the firewall this weekend between honey -do projects.

I made a hammer form out of a 2x4 on the band saw to match the contour of the firewall and beat some metal into submission. Still needs a little hammering but it's close enough for a test fit.   I decided to do recessed panels on the sides & I think I'll do raised panels on the front, but I've changes my mind so many times already, who knows.   This part of the firewall will get welded to the body. The rest will get welded to the chassis and the 2 will be bolted or riveted together (blind seam) from the inside  I think I spent more time in the lawn chair thinkin' about this than actually working on it. I kept changing the plans until I had a headache & finally decided to just do something. If it doesn't work I'll start over. I want to be able to take the body off, so that's why it's going to be a 2 pc. deal. Sort of the same reason I spent all that time on the billet aluminum hinges rather than just welding them to the chassis. Keeping the "A" pillars I'll still be able to use stock door weatherstripping and boxing in the firewall under the windshield I'll be able to keep the stock windshield wipers, got to keep it street legal right? |

|

|

|

|

| Thread Tools | |

| Display Modes | |

|

|