|

|

|

|

|

|

#1 |

|

Veteran Member

Join Date: Mar 2002

Location: Miles From Nowhere

Posts: 7,818

Likes: 2,909

Liked 5,126 Times in 1,954 Posts

|

Joe, I know you posted a generic question but it did Veer off from there. Just tell the people here what you do with your car and we'll probably have the answer. This is the stock super stock t e c h section

__________________

"We are lucky we don't get as much Government as we pay for." Will Rogers |

|

|

|

|

|

#2 |

|

Junior Member

Join Date: Apr 2016

Posts: 55

Likes: 1

Liked 20 Times in 16 Posts

|

Most threads on the 1st page with more views have been up for more than a month. This thread is only 5 days old.

Here's some pics of the original Hillbilly Clutch Slipper install using the hardware store VH440BL hydraulic screen door cylinder, everything was less than $20 at the time...    Like I said, the current 'tamer functions pretty much the same except with a much shorter cylinder. Just a simple, repeatable way to control throw-out bearing position during launch.

__________________

Grant website- http://ClutchTamer.com We make your non-adjustable clutch...ADJUSTABLE! Last edited by weedburner; 10-11-2022 at 06:57 PM. |

|

|

|

|

|

#3 |

|

Senior Member

Join Date: Jun 2011

Location: Ga.

Posts: 521

Likes: 7

Liked 13 Times in 11 Posts

|

Which was why I asked in THIS section....

With the exception of a few reply's , there wasn't much "ON POINT" participation. Some times the "sensitivity" or "specificity" of these forums is ridiculous. I was expecting answers on point with the question only. I never asked about clutch management. "At the point of bogging , wheel standing or blowing the tires off how does your best "launch" RPM coincide with either peak torque or peak power? Probably a question better directed towards the "back halved" crowd with a 13/31-14/32 tire.... Opinions?" You can close it. Last edited by joespanova; 10-12-2022 at 10:34 AM. |

|

|

|

|

|

#4 |

|

VIP Member

Join Date: Jun 2007

Location: from Vancouver BC Canada, now in Nova Scotia

Posts: 1,311

Likes: 317

Liked 1,104 Times in 302 Posts

|

May seem simplistic, by rather than worry about what the dyno sheet says, why not just try different launch RPMs, and see what goes the quickest? A dyno pull is quite different than how a car and engine work when going down the dragstrip, especially a stick car. On my low 10 second SB Ford, with a 4 speed and Soft Lok clutch, I find dropping the clutch at 6600 RPM, and shifting at 7000 produces the best 1/4 performance. Only real way to know is to experiment.

__________________

NHRA 6390 STK M/S 85 Mustang |

|

|

|

| Liked |

|

|

#5 |

|

Member

Join Date: Aug 2010

Posts: 212

Likes: 13

Liked 68 Times in 26 Posts

|

launch rpm, depends on track bite, and power, marginal tracks require less rpm, different tire press, etc, like rory says, takes seat time and testing to find what it likes or dislikes, i've never seen any charts about rpm, at launch versus rpm in traps, we launch at 6000, shift at 6500, traps is 7400 seems to be best setup, for us.

|

|

|

|

|

|

#6 | |

|

Junior Member

Join Date: Apr 2016

Posts: 55

Likes: 1

Liked 20 Times in 16 Posts

|

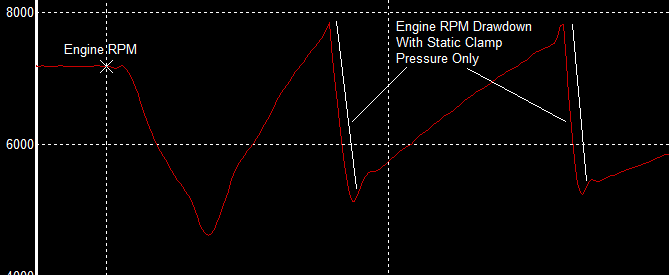

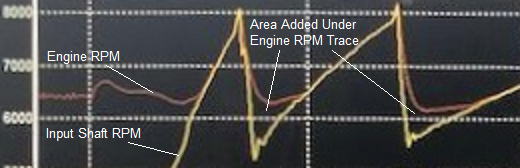

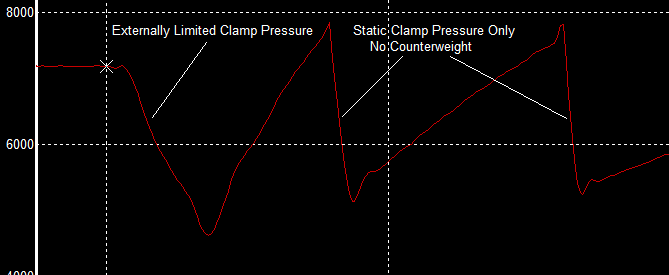

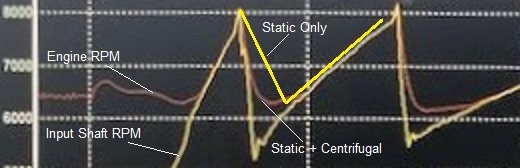

Quote:

Torque x RPM, highest average number wins if you can get all that power to the track consistently. Raising launch rpm adds area under the engine's rpm trace, which means the engine will produce more power strokes in that critical first second after launch. The clutch's engagement characteristics are among the most important adjustments you can make to a stick shift drag car, both for the launch as well as after the shifts. If you have a typical diaphragm, B&B, or non-adjustable Long style pressure plate that uses spring pressure only (no centrifugal assist), the engine rpm drawdown part of the engine rpm trace will be pretty linear, basically a straight line like on this graph below...  If you have a SoftLok style "adjustable slipper clutch" that uses counterweights in addition to spring pressure to clamp the disc, the part of the engine rpm trace where that clutch pulls the engine down will form a gradual curve. Because its centrifugal counterweight component relaxes as the clutch pulls engine rpm down, overall clutch clamp pressure relaxes as well. Note that engine rpm initially drops very quickly after the gear change (trace falls almost straight down), but then the trace begins to gradually curve as the clutch gradually loses it's ability to pull the engine down any further...  One feature of the curved engine rpm drawdown shape is that it adds area under the engine's rpm trace. If the above clutch had not slipped at all after the 1/2 shift, the ratio change dictates it would have pulled the engine down to around 5245rpm (input shaft speed) after the tires hooked back up. But because it was a SoftLok style clutch with a centrifugal component, clamp pressure relaxed as the engine lost rpm, which in-turn slowed down the rpm loss. Because the car was also gaining speed while the clutch was slipping, the delayed lockup point raised the minimum rpm after the shift to 6302 instead of drawing the engine all the way down to 5245rpm as predicted by the ratio change. That added clutch slip time tightened up the engine rpm operating band, which in-turn allows the engine to operate higher on the plateau of its HP curve. Going back to the static-only (no centrifugal assist) clutch graph below, another thing to note is that you can adjust the angle of engine rpm drawdown on the graph by adjusting the clutch's static clamp pressure. Note that angle of the drawdown after both shifts on the below graph are basically the same, while the drawdown angle after launch is still straight but the rpm is drawn out over a longer time period...  The above difference in drawdown angles was made possible by externally controlling throwout bearing position during launch. Basically the throw-out bearing was not allowed to fully retract during launch, which prevented the full force of the clutch's spring pressure from clamping the disc. The throw-out bearing was then allowed to retract shortly after launch, which in-turn increased the clutch clamp pressure available for the shifts. The angle of the drawdown during launch is adjusted via throw-out bearing position, the angle of the drawdown after the shifts is adjusted via static clamp pressure. You end up with more clutch slip during launch, less clutch slip after the shifts. Here's the SoftLok style curved drawdown shape compared to a straight drawdown after the shifts...  Notice how an adjustable static-only (no centrifugal assist) straight-line drawdown can be optimized to add even more area under the engine's rpm trace than the traditional SoftLok style curved drawdown. Also note that the initial draw down after the shift is not as steep. That flatter angle indicates energy is leaving the engine's rotating assy at a slower rate, which in-turn makes it easier to keep the tires stuck thru the shift. Because the engine is producing power at a quicker rate during the straight-line drawdown, clutch lockup occurs sooner which allows the engine to get a head start on its climb to the next shift point. When you add external throw-out bearing position control to the static only (no centrifugal assist) straight-line drawdown, you end up with a more consistent dead-hook launch that doesn't drag the engine down. It also really shines on a crappy track. The dead hook reduces the need to adjust tire pressure and launch rpm for the purpose of controlling wheelspeed. Without the need to control wheelspeed, you will likely be able to make use of less first gear ratio, which will in-turn allow tightening up the gear splits. Little gains here and there, but it all adds up. It's a lot like the quick automatic transmission cars. A less efficient coupling allows the engine launch higher and gain rpm faster while also reducing rpm loss after the shifts. The increase in power production shows up as more area under the engine rpm trace, and that added power more than offsets the loss of mechanical efficiency. In my opinion, in most cases the traditional SoftLok "adjustable slipper clutch" style clutch tune is becoming out-dated tech. First it limits your ability to take advantage of launch rpm, then it has a tendency to knock the tires loose after the shifts. Knocking the tires loose after the shifts is usually what prevents guys from making the switch to radials.

__________________

Grant website- http://ClutchTamer.com We make your non-adjustable clutch...ADJUSTABLE! Last edited by weedburner; 10-17-2022 at 02:12 PM. |

|

|

|

|

| Liked |

|

| Thread Tools | |

| Display Modes | |

|

|