|

|

|

|

|

|

#1 |

|

Member

Join Date: Jul 2006

Location: South Dakota

Posts: 153

Likes: 70

Liked 388 Times in 60 Posts

|

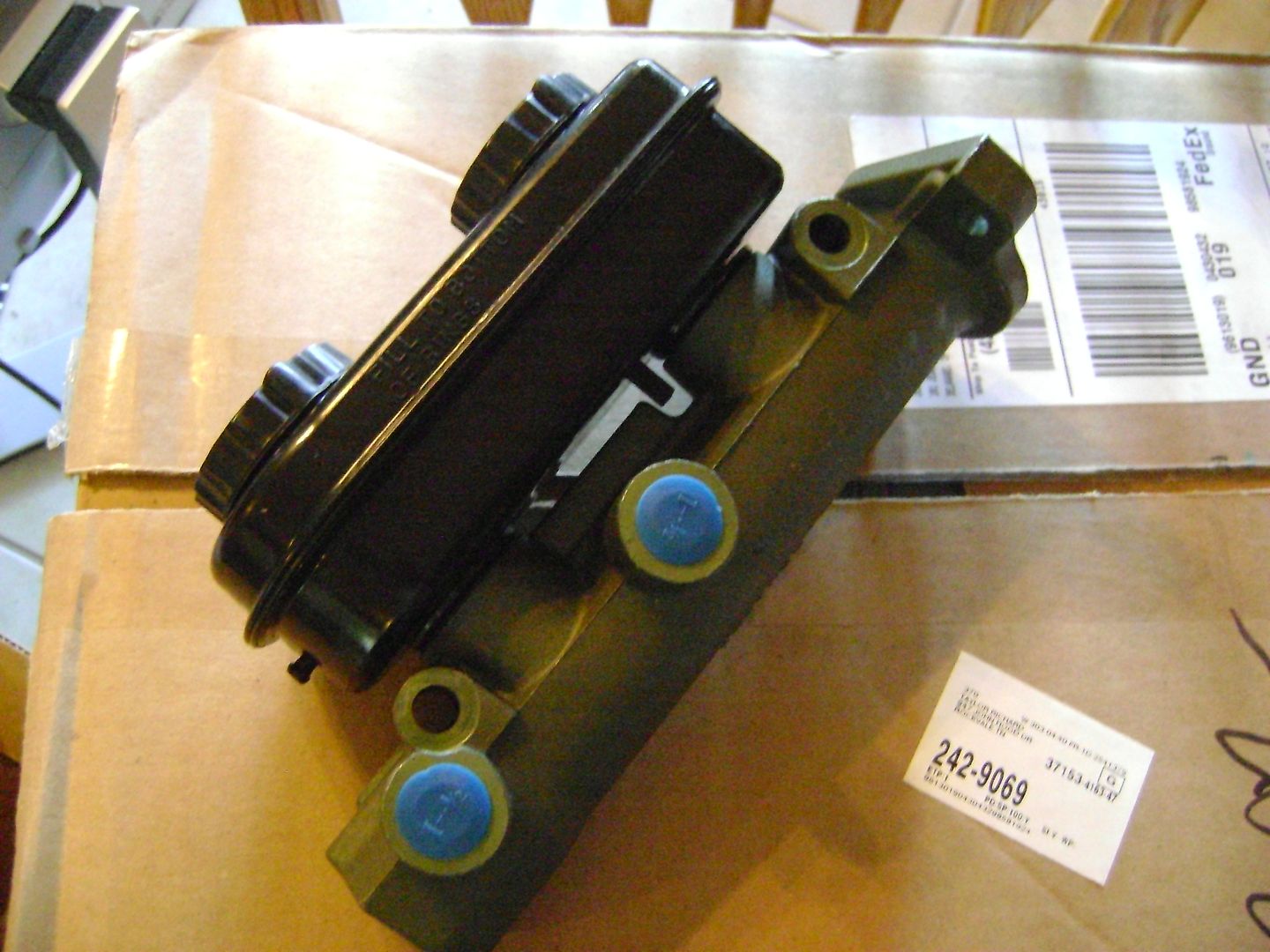

Al try this , will correct that lean condition!!!!

|

|

|

|

|

|

#2 |

|

VIP Member

Join Date: Dec 2002

Location: Lower Dakota territory

Posts: 1,180

Likes: 1,074

Liked 799 Times in 236 Posts

|

Geez Bob....that things about the size of the crankshaft in my 327!

Reminds me of the 'rubber' Stocker camshaft designed by (blank blank). The lobes grew as the RPM's went up! Reminds me of the 'rubber' Stocker camshaft designed by (blank blank). The lobes grew as the RPM's went up!  -Al -Al

__________________

"That'll never work....." |

|

|

|

|

|

#3 | |

|

Member

Join Date: Apr 2006

Posts: 243

Likes: 0

Liked 1 Time in 1 Post

|

Quote:

It will be hard to put one of Steve's BB in that thing and call it a 327 so....Ya, Sherwood can get the 'Shadow' to work a big stick to fit, and that old Nitro kit from the Pro guy will work fine. DB has a crate motor on order that you can use. Check and see if old Northwind has a valve train, also W.S. has some parts....more later. |

|

|

|

|

|

|

#4 |

|

VIP Member

Join Date: Dec 2002

Location: Lower Dakota territory

Posts: 1,180

Likes: 1,074

Liked 799 Times in 236 Posts

|

Front suspension apart for a freshen-up......bushings, control arm shafts, ball joints, etc. Will also treat it to some lightweight disc brakes. Once that's back together the motor will go back in:

Relocated and raised the shifter with some 6061 I had laying around:

__________________

"That'll never work....." |

|

|

|

|

|

#5 |

|

VIP Member

Join Date: Oct 2013

Location: Gulf Breeze, FL

Posts: 1,651

Likes: 8

Liked 33 Times in 16 Posts

|

That's clean Al...I really need to do something with our shifter as well.

__________________

Rich Taylor I/SA - 321 |

|

|

|

|

|

#6 |

|

VIP Member

Join Date: Dec 2002

Location: Lower Dakota territory

Posts: 1,180

Likes: 1,074

Liked 799 Times in 236 Posts

|

Rich, the round stock is 3/4". With a .750 counterbore, I went .125 deep in the plates as a register for the round stock, faced off the ends of the round in my lathe, drilled and tapped the ends of the round 1/4X20 and used a standard 82 degree countersink for the flat head Allen screws. You could also just have it TIG'd and simplify the deal.

Took longer to clean up the chips than make the part. Not really....... -Al

__________________

"That'll never work....." Last edited by Alan Nyhus; 01-04-2014 at 11:41 PM. |

|

|

|

|

|

#7 |

|

VIP Member

Join Date: Oct 2013

Location: Gulf Breeze, FL

Posts: 1,651

Likes: 8

Liked 33 Times in 16 Posts

|

What brake components are you going with? We ended up having to space the m/c off the firewall using the Bickel piston rod kit...had a high pedal and it was not fully retracting. http://www.jerrybickel.com/brake-kit...-jbrc1064.html

__________________

Rich Taylor I/SA - 321 Last edited by HandOverFist; 01-05-2014 at 12:18 AM. |

|

|

|

|

|

|