|

|

|

|

#201 |

|

Member

Join Date: Nov 2007

Location: Ontario Canada

Posts: 411

Likes: 1

Liked 19 Times in 7 Posts

|

I was under the assumption that when anything breaks in the rear end the trans is usually broke as well or needs to be checked. I bet the shaft got bent when the perches broke and or the driveshaft was rammed into the back of the trans to make the back of the case break like that. I went through two transmission cases last year (350 turbo) both broke in the bell housing. Checked and found the bolts that hold the lower engine mounts to the frame were loose. I also tossed the urethane trans mount in favour for a stock one and never had an issue since. With one solid mount and one stock appreakng mount theres going to be an issue specially if theres a hight difference. Your actually preloading the trans case when you tighten the trans mount bolts to the crossmember. The urethane mount will give a little....not alot. Another problem is with a 46 year old car that cant have any bars towards the front frame there is going to be some twist in the front sub frame. Weakest point...transmission. A rubber mount will allow it to move a bit without trying to twist the transmission in half. As far as the springs go in my opinion the split leafs are the best barr none...i had Tri City Competition springs prior to my Calvert stuff and it was night and day difference. If you are looking for ride height order a set of split monos with negative ride height but keep in mind if they will sag over time. Mine lowered itself enough to take preload out of the bars. Make sure the rear shackles are loose and move free. I have jam nuts on mine to keep them loose enough to move free and tight enough to keep them from deflecting side to side. Hope you can find the trans breaking issue. Nice crossmember too ill be looking into buying one of those.

__________________

Tony Valerio 1968 Camaro 1700 IHRA H/CM 1701 NHRA SS/?A |

|

|

|

|

|

#202 |

|

Senior Member

Join Date: Apr 2011

Location: Middletown, IN

Posts: 593

Likes: 0

Liked 0 Times in 0 Posts

|

CRate... do you run standard type bushing in the shackles? Or Alum?

__________________

1968 Bird/TRW 455/Home ported 13's, '70 Qjet,Holley Street Dominator manifold, Comp Solid FT, 10.817/122.30/1.440 Workin' on E/SA combo  3119 E/SA 3119 E/SA

|

|

|

|

|

|

#203 |

|

Member

Join Date: Nov 2007

Location: Ontario Canada

Posts: 411

Likes: 1

Liked 19 Times in 7 Posts

|

Stock replacement. I bought the global west bushing....one fell in and the other was .050 to big. So i sold them to a friend and my mission is to build a set once my lathe is hooked up. Global West did say they would build me a set but after seeing what they sent its a simple project for anyone with some basic machine shop experience.

__________________

Tony Valerio 1968 Camaro 1700 IHRA H/CM 1701 NHRA SS/?A |

|

|

|

|

|

#204 |

|

VIP Member

Join Date: Oct 2013

Location: Gulf Breeze, FL

Posts: 1,651

Likes: 8

Liked 33 Times in 16 Posts

|

I wouldnt put much effort in it...anything that fits the holes will be fine. The only thing that moves on mine are the thick side plates. I used slightly longer bolts and nyloc nuts to secure but not tighten the plates against the bushings...swings freely.

__________________

Rich Taylor I/SA - 321 |

|

|

|

|

|

#205 |

|

Member

Join Date: Nov 2007

Location: Ontario Canada

Posts: 411

Likes: 1

Liked 19 Times in 7 Posts

|

FYI the solid rear shackle bushing are a good idea they will stop any lateral movement and operate super smooth. Im constantly looking for a grease that will live and not move away from the bushing. I service the spings once every 3 races just to make sure that shackle is moving free and not bound up. I just had it all appart and tried ARP fastener lube on it. I was able to tighten the bolts all the way and the shackle still moved smooth. After a few hits at the track we will see if its still happy.

__________________

Tony Valerio 1968 Camaro 1700 IHRA H/CM 1701 NHRA SS/?A |

|

|

|

|

|

#206 |

|

Member

Join Date: Nov 2007

Location: Ontario Canada

Posts: 411

Likes: 1

Liked 19 Times in 7 Posts

|

I agree. I use old 3/8 polly locks on the top and a jam nut on the bottom with factory replacement shackles and bolts...LOL. works fine i think

__________________

Tony Valerio 1968 Camaro 1700 IHRA H/CM 1701 NHRA SS/?A |

|

|

|

|

|

#207 | |

|

VIP Member

Join Date: Oct 2013

Location: Gulf Breeze, FL

Posts: 1,651

Likes: 8

Liked 33 Times in 16 Posts

|

Quote:

I think those using a factory side plate with the welded thru bolt have more issues. Mine are seperate plates and bolts. I think those using a factory side plate with the welded thru bolt have more issues. Mine are seperate plates and bolts. Factory parts...

__________________

Rich Taylor I/SA - 321 Last edited by HandOverFist; 04-30-2014 at 01:16 AM. |

|

|

|

|

|

|

#208 |

|

VIP Member

Join Date: Oct 2013

Location: Gulf Breeze, FL

Posts: 1,651

Likes: 8

Liked 33 Times in 16 Posts

|

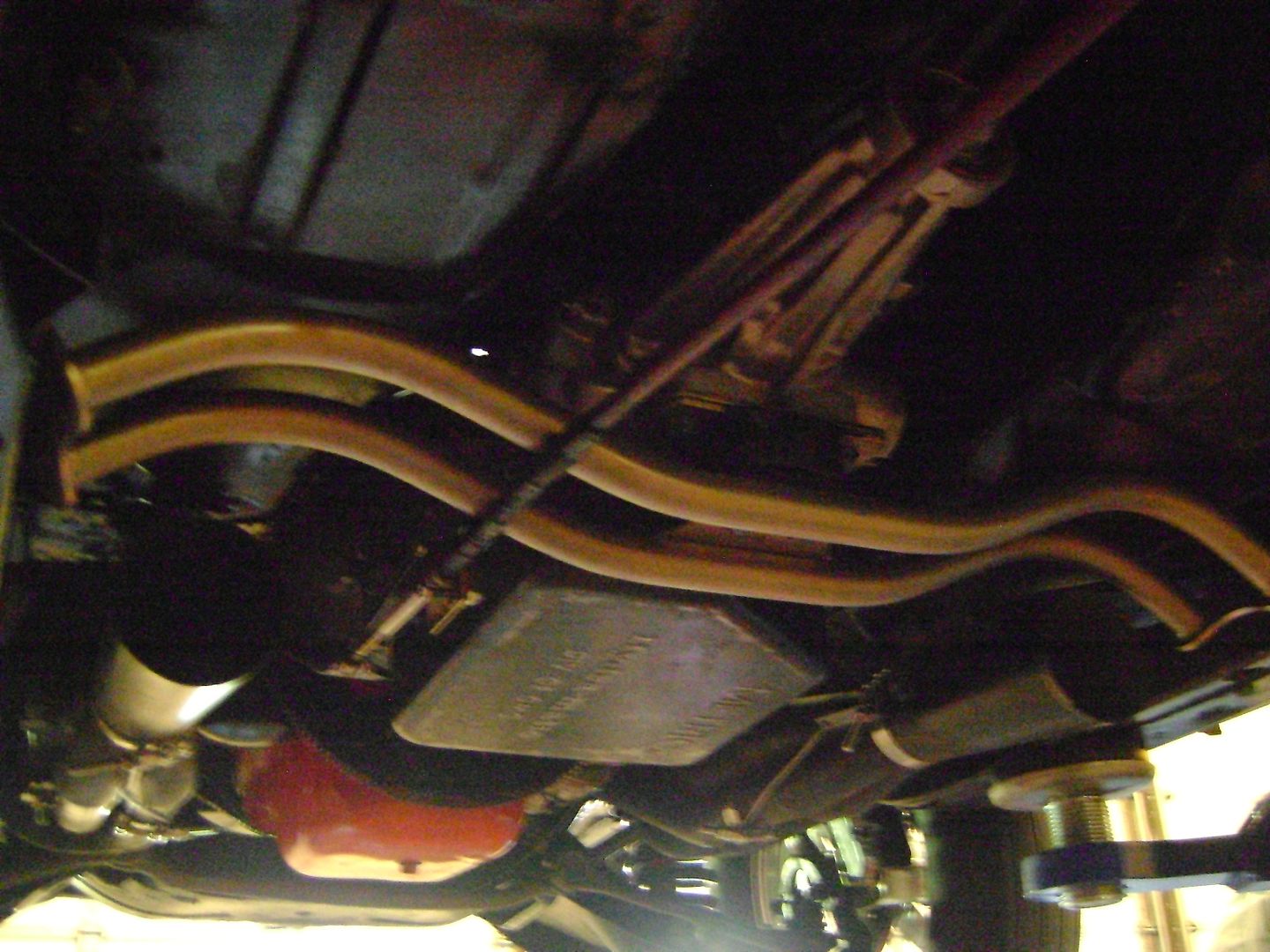

Side by side comparison of a 1310 joint vs a 1350...

Crossmember installed...

__________________

Rich Taylor I/SA - 321 |

|

|

|

|

|

#209 |

|

VIP Member

Join Date: Oct 2013

Location: Gulf Breeze, FL

Posts: 1,651

Likes: 8

Liked 33 Times in 16 Posts

|

Landrum 150# monos...hope these are the last say.

__________________

Rich Taylor I/SA - 321 |

|

|

|

|

|

#210 |

|

Senior Member

Join Date: Aug 2004

Location: Jacksonville, Florida

Posts: 808

Likes: 7

Liked 20 Times in 12 Posts

|

Rich,

Did you have any problem installing the cross member and did it seal lighter or heavier than the stock one? Thanks |

|

|

|

|

|

|