|

|

|

|

|

|

#1 |

|

Junior Member

Join Date: Apr 2016

Posts: 55

Likes: 1

Liked 20 Times in 16 Posts

|

Maybe the clutch wasn't broken in yet, that clutch should be fine at that power level. If the surfaces were freshly machined I could see the organic side pulling loose with too much grip while the metallic side was still slipping.

If it's pretty even 50/50 street strip, I would use that same PP and step up to a 900 series iron disc. Engagement would be a little harsh, but harsh engagement can be mechanically buffered without too much trouble. |

|

|

|

|

|

#2 |

|

Junior Member

Join Date: Apr 2016

Posts: 55

Likes: 1

Liked 20 Times in 16 Posts

|

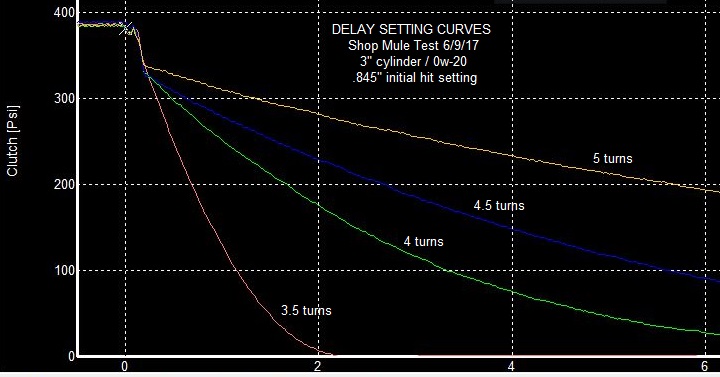

Here's an example of what I mean by a clutch can be mechanically buffered. These are a series of pressure curves from a hydraulic throwout bearing acting against a 2800lb Ram diaphragm PP, buffered with one of my ClutchTamers...

The lines represent different levels of clamp pressure that is initially withheld upon pedal release, then that withheld clamp is allowed to gradually come in at a slower rate. This allows the clutch to hit hard enough to launch the car effectively, but not so hard that the clutch either blows the tires off or causes the engine to bog. Basically it's just a different way to "adjust" a clutch's behavior to find the sweet spot. Here's a graph that shows different rates of feeding in the withheld clamp pressure...  Here's a link to my website that might help explain the concept... http://clutchtamer.com It's pretty easy to build something like this yourself using hardware store materials that might have been available back in the day. Such a scheme might not be in the spirit of a nostalgia racer, but neither will a modern adjustable clutch. Last edited by weedburner; 06-11-2017 at 01:45 PM. |

|

|

|

|

|

|