|

|

|

|

#1 |

|

Senior Member

Join Date: Jun 2011

Location: Ga.

Posts: 521

Likes: 7

Liked 13 Times in 11 Posts

|

At the point of bogging , wheel standing or blowing the tires off how does your best "launch" RPM coincide with either peak torque or peak power?

Probably a question better directed towards the "back halved" crowd with a 13/31-14/32 tire.... Opinions? |

|

|

|

|

|

#2 |

|

Member

Join Date: Apr 2022

Location: Noblesville,In

Posts: 108

Likes: 7

Liked 58 Times in 36 Posts

|

Most run slipper clutches

I will leave at 5600-6200 depending on the track and the clutch will slip so not to spin. Listen to a Prostock single or buy run. At the hit the motor doesn’t drop rpm it slips up in rpm and every shift it only drop 200 if any at all. Most doesn’t even lock up until 4th or 5th gear. I’m super stock it would 3rd or 4th My motor doesn’t do anything torque or horse power under 8k if this helps

__________________

SS/AH 328X |

|

|

|

|

|

#3 |

|

Member

Join Date: Dec 2010

Posts: 299

Likes: 3

Liked 36 Times in 26 Posts

|

What kinda of power,what type of trans, what kinda of car. Thing that help me on the bog, or lack of power at times,I put a grid in so I can change the timing in one gear for a certain rpm. Helped me out. I tried to post a graph but have not figured it out

|

|

|

|

|

|

#4 |

|

Member

Join Date: Dec 2010

Posts: 299

Likes: 3

Liked 36 Times in 26 Posts

|

I am well below my peak torque or horsepower

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Jun 2011

Location: Ga.

Posts: 521

Likes: 7

Liked 13 Times in 11 Posts

|

The question is intended to be a "generality" as to whether or not peak tq ( or power ) helped determine ( or influenced ) where you ended up ..relevant to launch RPM.

|

|

|

|

|

|

#6 |

|

Member

Join Date: Dec 2010

Posts: 299

Likes: 3

Liked 36 Times in 26 Posts

|

The goal was consistently. The track changes, so if the track is slick cause of no prep, and then you have first round with prep, you have to find how to avoid the difference. Had to work on getting the car to pull during the launch, consistently. If I go up and leave at 6k and rum it thru the gears it will be too fast. I only have to go 9.90

|

|

|

|

| Liked |

|

|

#7 |

|

Junior Member

Join Date: Apr 2016

Posts: 55

Likes: 1

Liked 20 Times in 16 Posts

|

I think the typical static+CW "slipper clutch" tune leaves a lot on the table.

The basic clutch tuning challenge for most in drag racing applications is that the ideal amount of clutch clamp pressure during launch is less than what's ideal after the shifts. The traditional adjustable static+CW clutch attempts to solve that problem consistently by using centrifugal weights in a way that makes clutch clamp pressure increase with engine rpm. Lowering launch rpm well below the shift rpm has the effect of relaxing the amount of centrifugal clamp applied, which can in-turn prevent the clutch from pulling the engine down below its torque peak during launch. Then by the time the engine reaches the shift point, clamp pressure has increased to the point where the clutch slips much less after the shifts. More slip during launch, less slip after the shifts. Problem solved? The adjustable static+CW clutch solution sounds great until you consider this- "driving into" an adjustable clutch at an averaged 6200rpm will produce 52 power pulses during that critical first second after dumping the clutch. But spinning at an averaged 8000rpm the engine will produce 67 power pulses over that same time period. That's a gain of 28% more power pulses during that critical first second after dumping the clutch due to higher launch rpm. Even if the engine makes more torque at an averaged 6200 vs 8000, it won't make 28% more torque at the lower rpm to make up the difference. Higher average rpm during launch definitely has the advantage as far as power production goes. Problem with the traditional "adjustable clutch" solution is that when you raise launch rpm you also increase clutch clamp pressure, which limits how far you can go without upsetting the chassis. I suspect that's a basic reason why James chooses to set his SS/AH car off at 6200 instead of 9500. There's also a difference in the amount of inertia energy stored within the engine's rotating assy. More energy stored prior to the start of the clock means more energy is available to move the car after the clock starts running. The key to exploiting launch rpm is finding a way to harness more launch energy without upsetting the chassis/tires with a harder hitting clutch. An alternative to the traditional static+CW method of clutch tuning is to vary clutch clamp pressure in a way that is not dependent on rpm, but rather by controlling clutch clamp pressure externally during launch via throw-out bearing position. This makes it possible to have two separate stages of clutch engagement that are independent of engine rpm- a 1st stage level of reduced clamp pressure that is optimized to take advantage of higher rpm launches, which then transitions to a 2nd stage level of full clamp pressure that's been optimized for harnessing energy release after the shifts. In the end, less energy gets wasted due to excessive wheelspeed spikes. The clutch also gets easier to tune when you abandon centrifugal weights and then crank-in just enough spring to hold after the shift into high gear. From there use a 2-stage clutch hit controller to control throw-out bearing position during launch. Completely eliminates the centrifugal vs base balancing act, as it allows you to adjust launch clamp pressure without affecting high gear clamp pressure. Far simpler way to tune a clutch, and you won't need help from an expert to dial it in. ...If it slips too much or not enough during launch (1st stage), you dial that in with the clutch hit controller from the driver's seat. ...If it slips too much or not enough after going into high gear (2nd stage), you know you need to adjust clutch spring pressure. There's also a consistency advantage in a dead hook launch vs trying to control wheelspeed.

__________________

Grant website- http://ClutchTamer.com We make your non-adjustable clutch...ADJUSTABLE! Last edited by weedburner; 10-07-2022 at 12:51 PM. |

|

|

|

| Liked |

|

|

#8 |

|

Senior Member

Join Date: Jun 2011

Location: Ga.

Posts: 521

Likes: 7

Liked 13 Times in 11 Posts

|

I'm not sure I'm getting what I expected out of the initial question.......clutch management wasn't the consideration here. Specifically , you could make the clutch work at a variety of RPMs......my consideration was the connection between "that" and making it work around / at / near , the aforementioned hypothetical engine torque / power point. In other words is the effort (through clutch tuning) made to "exploit" the engines peak points of either or just manage it to get the car to work with little regard to either.

Using my own as an example , with no change in the bell housing and enough base ( because I don't use a data logger ) to launch the car well enough to keep me near or well into decent 60 fts. I can apparently spin or wheel stand just by varying launch RPM. And a wheel stand could be very high , or very little with spin. So the initial thoughts are outside of the bellhousing ....leaning towards , am I changing the cars characteristics at launch because of how the engines power band comes into play ( way over peak torque ) or right at peak torque. It is likely the clutch CW has some input here.....BUT which has the greater influence? |

|

|

|

|

|

#9 |

|

VIP Member

Join Date: Mar 2007

Posts: 2,471

Likes: 631

Liked 1,984 Times in 597 Posts

|

Back years ago when I ran a stick in my car. The car was faster launching at high RPM. this was before all of the good clutch stuff and rev limiters we have now. I would leave at 9000 RPM and pull the shifter to second as quickly as possible. Then shift the remaining gears at 8000. The car liked a light flywheel 13 lb. Clutch was 1800 base as I remember with a six pad disc. Dead hook. I had 2 transmissions one 305 low and one with a 3.19 low. SS/I and SS/J. It was brutal on parts.

__________________

Mike Pearson 2485 SS |

|

|

|

| Liked |

|

|

#10 | |

|

Junior Member

Join Date: Apr 2016

Posts: 55

Likes: 1

Liked 20 Times in 16 Posts

|

Quote:

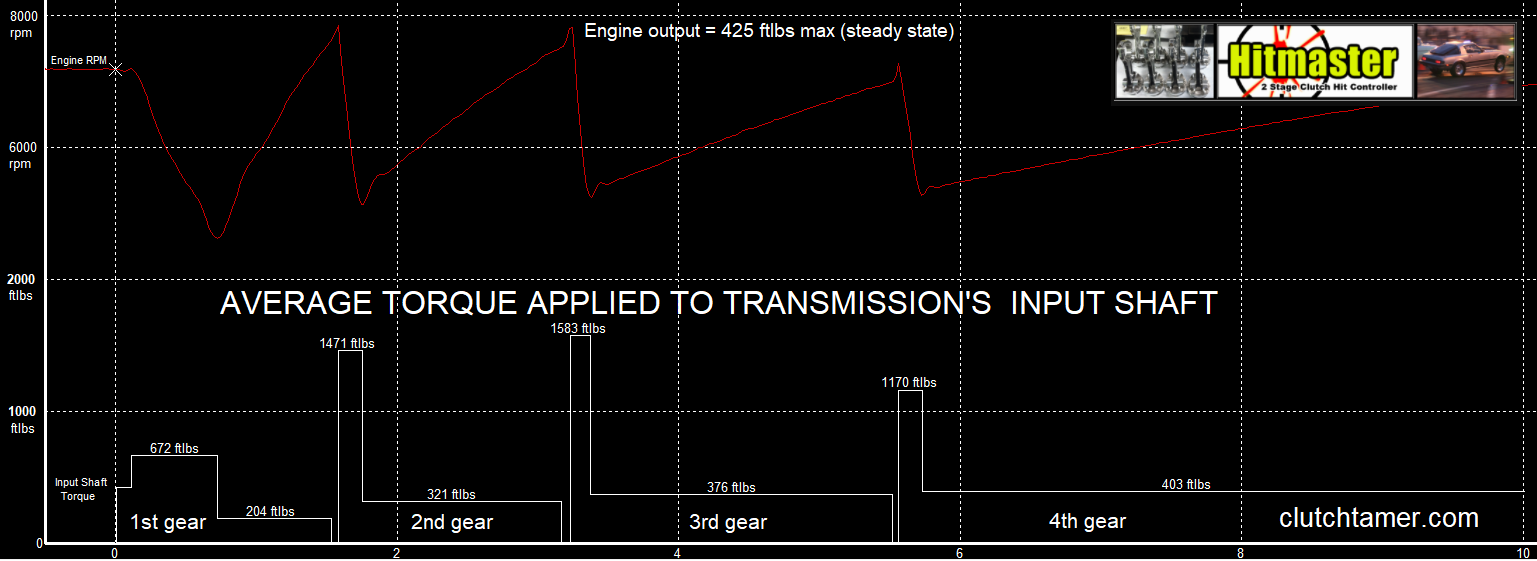

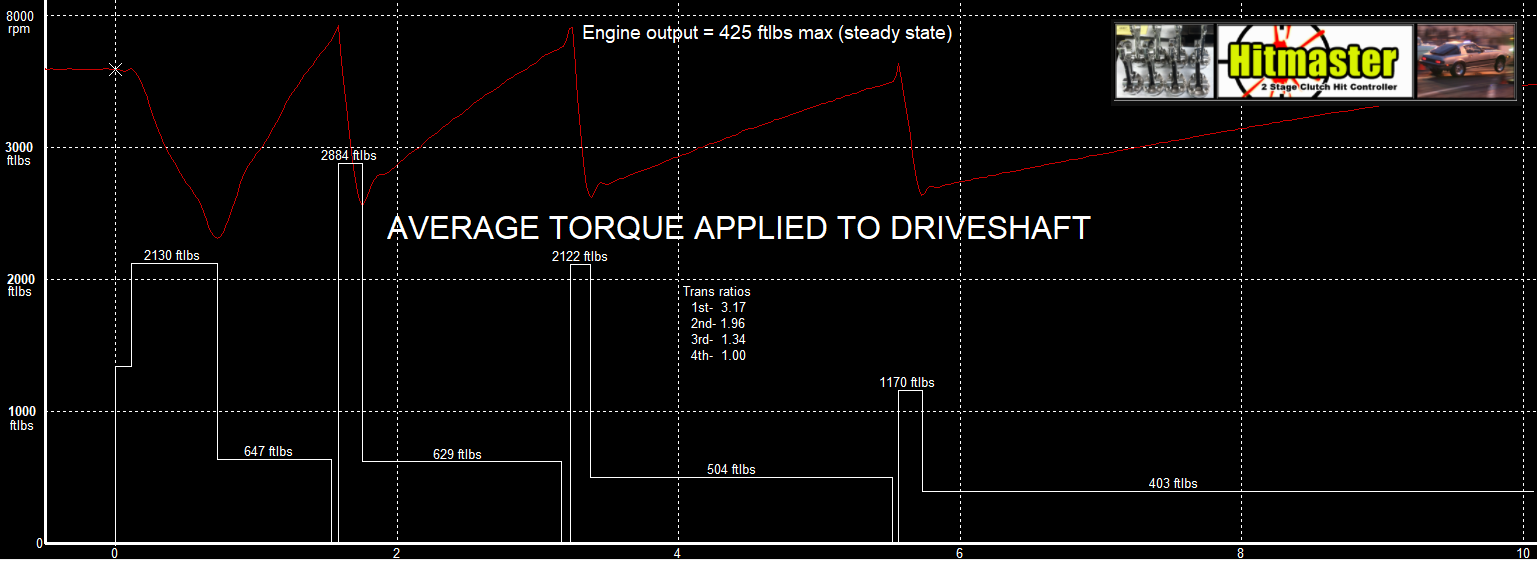

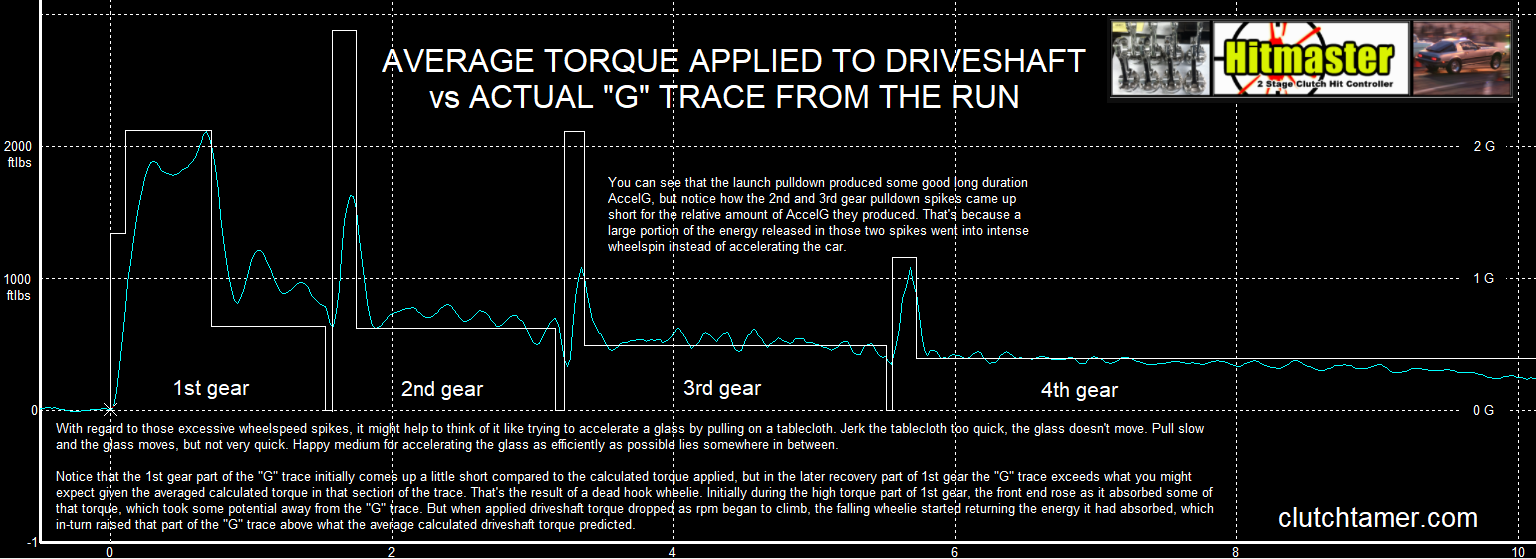

When you are launching way over the engine's peak torque, the clutch hits harder and your engine is likely initially losing rpm during launch. That loss of engine rpm adds torque to the transmission's input shaft. That extra torque due to stored energy exiting the engine's rotating assy, along with a harder hitting clutch, causes excessive wheelspin before the car gets a chance to transfer weight. When you are launching from a lower rpm closer to your engine's torque peak, the clutch slips more and the engine may or may not lose rpm. If it doesn't lose rpm, the input shaft will only see engine torque during launch. If you launch below the engine's torque peak, the engine will gain rpm during launch. In that case the engine's rotating assy will absorb some of the engine's torque, which will in-turn reduce the torque that the input shaft sees. Note on the graph below that this 425ftlb engine puts out way more than 425ftlbs when it is losing rpm, and much less than 425ftlbs when it is gaining rpm. That's due to the engine's rotating assy releasing and absorbing energy as it loses or gains rpm...  Here's those calculated input shaft torque numbers multiplied by the transmission ratios to show driveshaft torque...  If you are wondering how accurate those calculated torque numbers might be, here's those calculated driveshaft torque numbers compared to the actual AccelG trace from that pass...

__________________

Grant website- http://ClutchTamer.com We make your non-adjustable clutch...ADJUSTABLE! |

|

|

|

|

| Liked |

|

|

|